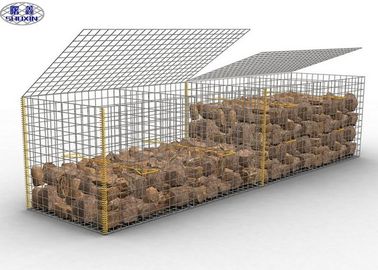

Rust Proof Galfan Coated Welded Gabion Box / Zinc-Al Coated Welded Gabion

Welded gabion box is high quality steel mesh. They can be filled on site with hard durable stone materials to form mass gravity retaining structures. Owing to their inflexibility, welded gabions can not adapt to differential settlement or be used in water courses. In comparison with woven wire gabions, welded gabions offer a higher strength. In order to meet diffferent project requirements, various wire diameters and unit sizes available for welded gabion boxes.

Details of welded gabion box :

Material: Galvanized steel wire or Galfan / zinc-5%aluminum wire

Use Life: 10-20 years

Price: 9.8$-59.8$/set

Wire diameter: 3.0mm- 6.0mm

Aperture: 25*50mm 50*50mm 75*75mm 76.2*76.2mm 50*100mm etc

Gabion size:1*1*1m 1*0.5*1m 1*1*2m or as request.

Finish: hot dipped galvanized,galfan wire,PVC coated

Welded method: welded after galvanized or galvanized after welded

Packing: Wrapped with shrink film then packed in wooden fumigation pallet or iron pallet

| Nominal Box sizes ( m) |

No. of diaphragms (no.) |

Capacity per box (m3) |

| 1.0 × 1.0 × 0.5 |

Nil |

0.50 |

| 1.0 × 1.0 × 1.0 |

Nil |

1.00 |

| 1.5 × 1.0 × 1.0 |

Nil |

1.50 |

| 2.0 × 1.0 × 0.5 |

1 |

1.00 |

| 2.0 × 1.0 × 1.0 |

1 |

2.00 |

| 3.0 × 1.0 × 0.5 |

2 |

1.50 |

| 3.0 × 1.0 × 1.0 |

2 |

3.00 |

| 4.0 × 1.0 × 0.5 |

3 |

2.00 |

| 4.0 × 1.0 × 1.0 |

3 |

4.00 |

Welded gabion box advantages:

- Blends easily and harmoniously with the natural surroundings.

- Low cost alternative to concrete or masonry structures.

- Very high resistance to natural forces due to better tensile strength.

- Can withstand any unpredictable movement or settlement without loss of stability.

- Simple and speedy installation, making it cost effective.

- Quality finish and appearance is more aesthetically pleasing.

- More rigid than woven mesh resulting in a more uniform finish when built.

- Quicker and cheaper to install than Woven Mesh gabions because no pre-stretching required.

- Special gabions sizes and mesh such as gabions with 4mm front mesh and 3mm mesh else can be available.

How to install welded gabion box?

Step 1. Ends, diaphragms, front and back panels are placed upright on the bottom section of wire mesh.

Step 2. Secure panels by screwing spiral binders through the mesh openings in adjacent panels.

Step 3. Stiffeners shall be placed across the corners, at 300mm from the corner. Providing a diagonal bracing, and crimped over the

line and cross wires on the front and side faces. None are needed in interior cells.

Step 4. Gabion box filled with graded stone by hand or with a shovel.

Step 5. After filling, close the lid and secure with spiral binders at the diaphragms, ends, front and back.

Step 6. When stacking tiers of the welded gabion box, the lid of the lower tier may serve as the base of the upper tier. Secure with

spiral binders and add pre-formed stiffeners to exterior cells before filling with graded stones.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!