Heavy Galvanized Iron Wire Mesh Sand-filling Mil10 Defensive Barrier Wall HESCO Military Barriers

Sand-filling HESCO Military Barriers Description:

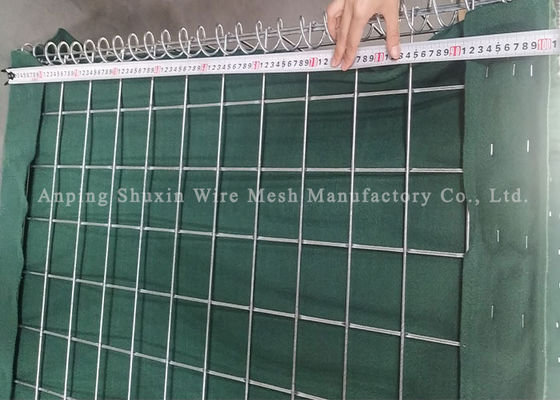

1. Wire diameter: 4-5mm

2. Mesh size: 3x3 inches (7.62*7.62 cm)

3. Panel Size: 13 species

4. Application: used for any security protection and sudden attack

5. Geotextiles: Heavy Non-woven Polypropylene

6. Color: gray, military green, sand, etc

7. Surface Treatment: Hot Dip Galvanizing, Galvanizing Wire

8. Packaging: Packaging with shrink film or pallet

1.Introduction

Hot dip galvanized gabion boxes with geotextile are also called fortresses, protective walls, sand cages, welded gabion boxes, etc. This is a multi-cellular system made of galvanized welded mesh and lined with non-woven fabric. The provided connection extension and connection unit may be used. It is easy to install and requires minimal manpower and commonly available equipment. After expansion, it is filled with sand and stones, and then welded with gabion barriers like defense walls or bunkers. It is widely used for military defense and flood control.

2. Working principle:

It is made of galvanized welded mesh plate, spring belt and other accessories, which can be filled with sand, soil, cement and stone, and can be used alone or connected by some defense barriers.

3. Quality assurance:

Our factory has been verified on site by SGS Group, the world's leading inspection company. Our products strictly follow ISO9001, SGS and CE certification. Our products comply with BS EN 10244-2:2009 and BS EN 1208-2:2012

Sand-filling HESCO Military Barriers Details

| Type |

Height

(M)

|

Width

(M)

|

Length

(M)

|

Internal Cells |

| SX-mil1 |

1.37 |

1.06 |

10 |

9 |

| SX-mil2 |

0.61 |

0.61 |

1.22 |

2 |

| SX-mil3 |

1.0 |

1.0 |

10 |

10 |

| SX-mil4 |

1.0 |

1.52 |

10 |

10 |

| SX-mil5 |

0.61 |

0.61 |

3.05 |

5 |

| SX-mil6 |

1.68 |

0.61 |

3.05 |

5 |

| SX-mil7 |

2.21 |

2.13 |

27.74 |

13 |

| SX-mil8 |

1.37 |

1.22 |

10 |

9 |

| SX-mil9 |

1.0 |

0.76 |

9.14 |

12 |

| SX-mil10 |

2.21 |

1.52 |

30.5 |

20 |

| SX-mil11 |

1.22 |

0.3 |

1.22 |

2 |

| SX-mil12 |

2.13 |

1.06 |

33 |

30 |

| SX-mil19 |

2.74 |

1.06 |

3.18 |

6 |

Sand-filling HESCO Military Barriers Application:

1. Military fortifications Most armies use defense barriers to build military fortifications because they can be stacked on top of each other. You can change the width and height according to your requirements. More simple and flexible.

2. Shooting range Nowadays, many people use defense barriers to build shooting ranges because of its high defense strength and safety.

3. Flood control Defense barriers are becoming more and more popular and easy to assemble, and good permeability. Most countries near coastlines choose defense barriers as flood prevention walls. Even around the hotel, they erected protective walls.

- Peripheral security and defense wall

- Equipment protection

- Shelter for personnel and materials

- Observation point

- Defensive firing position sentry

- Explosive and contraband search area

- Highway inspection station

- Border crossing checkpoint

- Protect existing structures

- Flood control retaining wall beach erosion

- Coastal Area Protection Project

Sand-filling HESCO Military Barriers Advantages:

1. Secure & reliable

Once filled with soil, sand or gravel, forms a solid and strong barrier with exceptional strength and structural integrity to protect personnel and equipment from enemy fire. For example:

Two feet thick barriers can be used to stop rifle bullets and shell fragments.

Four feet thick barriers can prevent most car bombs.

Five feet thick barriers is ideal for preventing penetration and explosion fragments from rocket propelled grenade.

2. Convenient usage

HESCO bastion barrier can be used in separate cell or some cells joined together by joint pins to suit different needs of your projects. Almost any locally filling material can be used such as soil, sand, gravel, crushed rock and various other granular materials.

3. Labor saving design

Can be collapsed and stacked on pallets for easy package, handling and transport, so that it efficiently saves labor cost.

4. Quick & easy assembly

Provides the easiest deploy methods - just unfold it and fill it using minimal manpower or commonly available equipment. Previously, sandbag barrier is considered a slow undertaking as a person can only fill about 20 sandbags per hour. Yet our KNSCO do ten times the work.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!